SAE8620

| 8620 is a low nickel – chromium – molybdenum medium hardenability, case hardening (carburizing) steel, generally supplied in the as rolled condition with a maximum brinell hardness of 280 (Rc30).Characterised by good core strength and toughness in small to medium sections with case hardness up to Rc62 when carburized, hardened and tempered.8620 can also be used (uncarburised) as a high tensile steel, which when suitably hardened and tempered can be utilized for various applications requiring good tensile strength and reasonable toughness.Pre hardened and tempered (uncarburized) 8620 can be further surface hardened by nitriding but will not respond satisfactorily to flame or induction hardening due to its low carbon content.8620 (carburized) is used extensively by all industry sectors for light to medium stressed components and shafts requiring high surface wear resistance with reasonable core strength and impact properties.Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined Shafts, Ratchets, Sleeves etc |

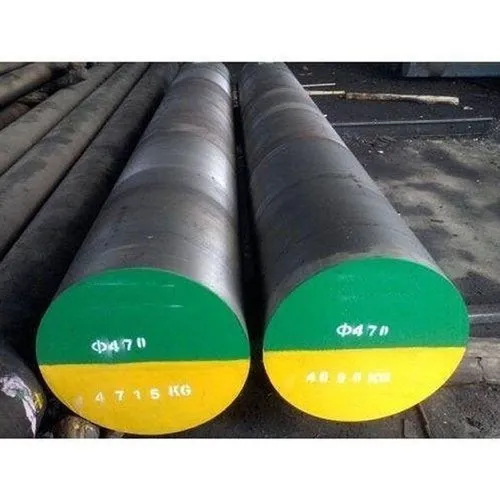

| Colour Code | Stocked Sizes | ||

Yellow (Bar End) | Rounds | 10 mm to 260 mm Diameter | |

| Bar Finish | |||

| Peeled, Turned or Hot Rolled | |||

| Related Specifications | |

| Australia | AS 1444-1996-8620/8620H |

| Germany | W.Nr 1.6523 DIN 21NiCrMo2 |

| Great Britain | BS970: PART 3: 1991 805 M20 BS970: 1955 – EN362 |

| Japan | JISG 4052 SNCM 220H |

| USA | SAE 8620 AISI 8620 ASTM A29/A29M 1991 8620 UNS G86200 |

| Chemical Composition | ||

| Min. % | Max. % | |

| Carbon | 0.17 | 0.23 |

| Silicon | 0.10 | 0.40 |

| Manganese | 0.60 | 0.95 |

| Nickel | 0.35 | 0.75 |

| Chromium | 0.35 | 0.75 |

| Molybdenum | 0.15 | 0.25 |

| Phosphorous | 0 | 0.04 |

| Sulphur | 0 | 0.04 |

| Typical Mechanical Properties For Core – Carburised and Oil Quenched at 840 oC | ||||||||||||||||||

| Section Size | 11 mm | 30 mm | 63 mm | |||||||||||||||

| Tensile Strength Mpa | Min | 980 | 780 | 690 | ||||||||||||||

| Max | 1270 | 1080 | 930 | |||||||||||||||

| Yield Strength Mpa | Min | 785 | 590 | 490 | ||||||||||||||

| Elongation 5.65√S0 % | Min | 9 | 10 | 11 | ||||||||||||||

| Charpy Impact J | Min | 41 | 41 | |||||||||||||||

| Hardness HB | Min | 290 | 235 | 205 | ||||||||||||||

| Max | 375 | 320 | 275 | |||||||||||||||

| Hardness RC | Min | 31 | 23 | 16 | ||||||||||||||

| Max | 41 | 35 | 29 | |||||||||||||||

| Typical Mechanical Properties – As Rolled | ||||||||||||||||||

| Tensile Strength Mpa | 820 | |||||||||||||||||

| Yield Strength Mpa | 590 | |||||||||||||||||

| Elongation on 5.65√S0 % | 22 | |||||||||||||||||

| Hardness | HB | 240 | ||||||||||||||||

| Rc | 24 | |||||||||||||||||

| Typical Mechanical Properties – Water Quenched at 830oC and Tempered as Indicated * | ||||||||||||||||||

| Tempering Temperature oC | 205 | 425 | 650 | |||||||||||||||

| Tensile Strength Mpa | 1050 | 930 | 700 | |||||||||||||||

| Yield Strength Mpa | 765 | 800 | 556 | |||||||||||||||

| Elongation on 5.65√S0 % | 18 | 20 | 30 | |||||||||||||||

| Izod Impact J | 80 | 110 | 140 | |||||||||||||||

| Hardness | HB | 311 | 275 | 207 | ||||||||||||||

| Rc | 34 | 29 | 16 | |||||||||||||||

| *Section Size 25 mm

Can be used in the Hardened and Tempered (uncarburised) condition for shock resisting shafts and parts with tensile strengths up to 800 Mpa, plus reasonable toughness possible in sections up to 100 mm.8620 is however generally used in the carburised condition with heat treatment details as follows. | ||||||||||||||||||

| Forging | ||||

| Heat to 1150oC and hold until temperature is uniform throughout the section. Soaking time at forging temperature should be as short as possible to avoid heavy scaling and excessive grain growth. This will vary depending on furnace conditions but 15 minutes per 25 mm of section may be used as a guide.Do not forge below 850oC.

Following completion of forging operation, work piece should be cooled as slowly as possible in sand or dry lime etc. Note: Case hardening steels due to their low carbon content are less susceptible to cracking than medium or high carbon steels, and may therefore be heated and cooled more rapidly. | ||||

| Heat Treatment | ||||

| Annealing | ||||

| Heat to 820oC – 850oC, hold until temperature is uniform throughout the section and cool in furnace. | ||||

| Caburizing | ||||

| Pack, salt or gas carburize at 900oC – 925oC, holding for sufficient time to develop the required case depth and carbon content, followed by a suitable hardening and tempering cycle to optimise case and core properties. | ||||

| Hardening | ||||

| Refer Refining & Hardening. | ||||

| Nitriding | ||||

| 8620 suitably hardened and tempered (uncarburised) will respond to nitriding giving a surface hardness up to Rc 60.Nitriding is carried out at 490oC – 530oC followed by slow cooling (no quench), reducing the problem of distortion. During the initial heat treatment the tempering temperature employed should be higher than the nitriding temperature. | ||||

| Normalizing | ||||

| Heat to 900oC – 925oC, hold until temperature is uniform throughout the section. Soak for 10 – 15 minutes and cool in still air. | ||||

| Refining & Hardening | ||||

| Core Refine | ||||

| Slow cool from carburizing temperature and re-heat to 840oC – 870oC, hold until temperature is uniform throughout the section, quench as required in water, oil or air cool. | ||||

| Case Hardening | ||||

| Following core refining, re-heat to 780oC – 820oC, hold until temperature is uniform throughout the section, and quench in oil.Temper immediately while still hand warm. | ||||

| Single Refine* | ||||

| Direct Quench: Cool from carburizing temperature to 820 oC – 840 oC, hold until temperature is uniform throughout the section. Quench in oil. Temper immediately while still hand warm.Or: Cool from carburizing temperature to room temperature, re-heat to 820 oC – 840 oC and hold until temperature is uniform throughout the section and quench in oil. Temper immediately.

*Suitable for fine grained steels only. | ||||

| Stress Relieving | ||||

| Heat to 630oC – 650oC, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm section, and cool in still air. | ||||

| Tempering | ||||

| Heat to 150oC – 200oC as required, hold until temperature is uniform throughout the section, soak for 1 – 2 hours per 25 mm of section, and cool in still air.N.B. Tempering will improve the toughness of both case and core, with only a slight reduction in core strength and case hardness. It will also reduce the susceptibility of the case to grinding cracks. | ||||

| Notes on Heat Treatment | ||||

| Heating temperatures, rate of heating, cooling and soaking times will vary due to factors such as work piece size/shape also furnace type employed, quenching medium and work piece transfer facilities etc..Please consult your heat treater for best results. | ||||

| Machining | ||||

| 8620 in the as rolled as supplied condition, has very good machinability and all operations such as turning, drilling, milling and tapping etc. can be carried out satisfactorily as per machine manufacturers recommendations for suitable tool type – feeds and speeds. | ||||

| Welding | ||||

| 8620 is readily weldable in the as rolled as supplied condition. Following welding, the work piece immediately upon cooling to hand warm should be stress relieved at 630oC – 650oC if possible.

N.B. Welding in the carburized and heat treated conditionis not recommended. | ||||

| Welding Procedure | ||||

| Welding of 8620 should always be carried out using low hydrogen electrodes – please consult your welding consumables supplier. | ||||

| Suggested Pre-heat Temperature | ||||

| Section | 40mm | 50mm | 75mm | 150mm |

| oC | 25 | 40 | 100 | 150 |

| Post Welding | ||||

| Allow to cool in still air. Alternatively cover in sand or dry lime etc.. | ||||

Interlloy believes the information provided is accurate and reliable. However no warranty of accuracy, completeness or reliability is given, nor will any responsibility be taken for errors or omissions.