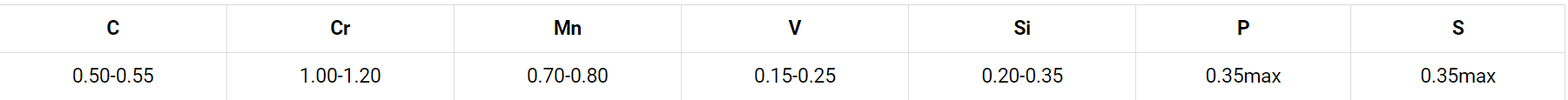

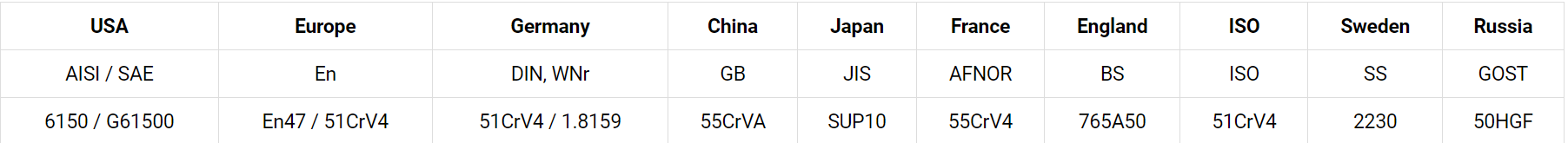

Bharti Steel Enterprises Supplies and Stocks EN47 spring steel is a Chromium Vanadium type spring steel supplied in as rolled as well as spheroidize annealed condition. EN47 spring steel is appropriate for oil hardening and tempering. When used in the oil hardened and tempered condition EN47 spring steel combines spring characteristics with good wear and abrasion resistance. When hardened EN47 spring steel offers excellent durability and shock resistance which make it a proper alloy spring steel for parts exposed to stress, shock and vibration. EN47 spring steel is also known in various standards as 50CrV4 or 51CrV4 or AISI 6150 or DIN 1.8159 spring steel in other countries.

APPLICATIONS

EN47 spring steel, highlight the advantage is great hardenability, another hot working performance, comprehensive mechanical properties, decarburization resistance is additionally great big cross section of various important spring. For example, automobile, locomotive, large plate spring, spring etc. SUP10 spring steel is mainly used for heavy vehicles, tractors, industrial production load, stress and the diameter of the larger plate spring and helical spring. It is also used widely in the motor vehicle industry and many general engineering applications. It is also suitable for applications that require high tensile strength and toughness. Typical applications include crankshafts, steering knuckles, gears, spindles and pumps.

FORGING

Forge at 1050°C. Do not work this steel when it has fallen below 840°C.

ANNEALING

Heat slowly to 820-840°C, soak well. Cool slowly in the furnace.

( Our annealing is done in electric furnace to avoid decarburization. )

HARDENING

Pre heat gradually to 650-700°C and completely soak. Continue heating to the final hardening temperature of 830-860°C and enable the component to be heated through. Quench in oil.

TEMPERING

Temper the EN47 spring steel component immediately after quenching whilst tools are still hand warm. Re-heat to the tempering temperature then soak for one hour for every 25 millimeter of aggregate thickness (2 hours minimum) cool in air. For most applications tempering of this grade will be between 400-600°C.

HEAT TREATMENT

Heat treatment temperatures, including rate of heating, cooling and soaking times etc. will vary due to factors such as the shape and size of each component. Other considerations during the heat treatment process include the type of furnace, quenching medium and workpiece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of EN47 spring steel.

Bharti Steel is a renowned steel Stockist with an rich history and a strong presence in the industry. Founded in [1970], we have grown to become a trusted name in the steel sector, known for our commitment to quality, innovation, and customer satisfaction.